Smart Warehousing – Trends, Benefits, and Technologies

The landscape of industrial parks, logistics and supply chain management is continuously evolving and efficiency is the name of the game. Warehouses, once seen as a mere storage space, have now transformed into a dynamic hub of operations, thanks to the integration of smart technologies. These smart warehousing innovations not only streamline processes but also enhance productivity and accuracy. And Magna Star Industrial Park has just the right space for it.

Smart warehousing involves using advanced technology and tailored strategies to efficiently manage inventory. This includes automating tasks and quality procedures, prioritizing the wellbeing of employees, and having a keen grasp of worldwide logistics and supply chain trends.

Smart Warehouses on the Rise

While only 20% of warehouses rely on automation today, there’s been a significant uptick in investment in this sector. A recent research further suggests that the market of smart warehousing is projected to reach approximately ₹31.3 lakh crore in 6 years. It is also estimated that nearly 30% of warehouses will adopt automated techniques this year.

Overall, the market size of smart warehousing in grade A logistics parks tends to increase at a 14.31% rate by 2031.

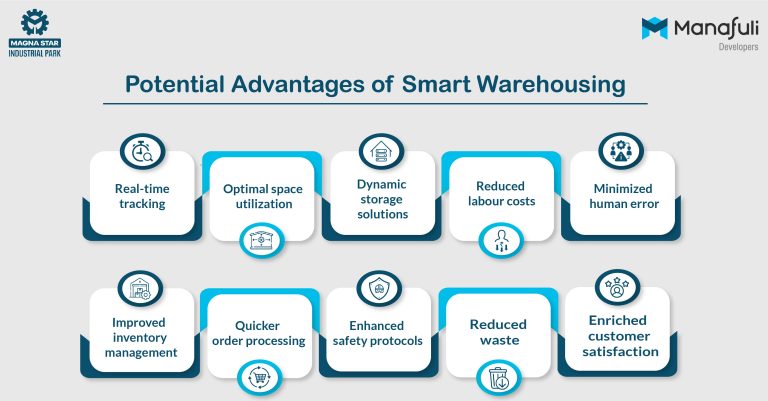

Potential Advantages of Smart Warehousing

By integrating advanced technologies and data-driven processes, smart warehousing in industrial park spaces optimizes operations and delivers unparalleled efficiency and agility to modern supply chains.

- Real-time tracking

- Optimal space utilization

- Dynamic storage solutions

- Reduced labour costs

- Minimized human error

- Improved inventory management

- Quicker order processing

- Enhanced safety protocols

- Reduced waste

- Enriched customer satisfaction

Top 7 Smart Warehousing Technology Picks to Elevate Efficiency

In today’s tech revolution, business parks include warehouses with major upgrades. They’re moving towards using robots and AI. This shift is turning warehouses into smart, efficient hubs. This change is helping the environment too.

1. Warehouse Management Systems (WMS)

WMS is essential in smart warehousing. These systems integrate various tasks like inventory management and order processing into one platform. They use smart algorithms to organize warehouse layouts, automate tasks, and manage resources efficiently.

With real-time data and customizable dashboards, managers can make informed decisions to boost productivity and meet customer needs.

Using a WMS offers many benefits like better visibility across the supply chain, accurate forecasting, and reduced expenses through efficient scheduling. Plus, it also fosters better relationships with suppliers and improves customer service.

Overall, a WMS ensures smooth operations and allows for ongoing optimization strategies.

2. Automated Guided Vehicles (AGVs)

In smart warehouses, manual labour and heavy lifting have been replaced by AGVs. These self-guided vehicles use sensors and advanced navigation systems to transport goods safely and swiftly without human intervention. They handle tasks like moving pallets, containers, and fragile items, reducing accidents and boosting efficiency.

AGVs also excel in storing and retrieving products, managing tasks such as rack storage, reel storage, and loading and unloading trailers automatically.

This, however, needs more space vehicles to move freely. Thankfully, Magna Star Industrial Park has the necessary space available to establish such a setup.

3. RFID Technology

Another smart warehousing technology is Radio-frequency identification (RFID). It is a modern way to manage inventory efficiently. It replaces traditional paper tracking methods with digital tags. These tags use radio waves to communicate with scanning systems, recording item details instantly.

They are small and cost-effective, attaching to products or pallets. RFID technology allows for quick and easy scanning of multiple items at once. These scanners provide real-time data to your warehouse management system.

4. Cobots

Cobots are collaborative robots designed to work alongside human employees in warehouses as well as logistics parks. While they require significant investment and infrastructure upgrades, they greatly improve workflow efficiency. Because it retains the existing processes and layouts while benefitting from the optimized operations, it is an ideal technology for smart warehousing.

5. IoT Networks

The Internet of Things (IoT) is a big idea that guides how you manage your warehouse. It helps by spotting problems early, which could cause trouble in the supply chain. Such sensors in smart warehousing keep an eye on things like temperature and moisture.

IoT can integrate shipping data, vehicle tracking, and product information to combat theft, counterfeit products, and spoilage. This is a really supportive technology for business parks too. In fact, owners of industrial park spaces at Magna Star can integrate their plant with IoT for the hassle-free running of their business.

Therefore, in a nutshell, it streamlines inventory management and workforce planning, and enhances customer satisfaction by speeding up processes and delivery times.

6. Automated Storage (AS) and Retrieval Systems (RS)

These smart warehousing technologies, like pallet lifters, conveyors, and warehouse control systems, have been in use for a long time. They’re sturdy and dependable, helping handle products efficiently alongside human workers. While they were once seen as pricey and rigid, today’s systems are becoming more streamlined while maintaining their advantages like lower labour costs and improved accuracy.

7. 5G

Finally, it is the 5G technology. 5G is revolutionizing warehousing connectivity, facilitating the integration of IoT devices for enhanced performance. By offering lower latency and greater bandwidth, 5G networks enable seamless tracking of moving objects, improving order processing and fulfilment.

This technology also supports navigation tools for Automated Mobile Robots (AMRs), reducing labour costs and enhancing workplace safety.

Additionally, by interconnecting sensors and machines, 5G optimizes complex operations. This speeds up smart warehousing and ensures precision and efficiency throughout.

Environmental Responsibility in Smart Warehousing

Smart warehousing technologies extend beyond just hardware and software; they involve fostering a purpose-driven culture within the warehouse itself. This entails building a diverse and inclusive workforce, where various perspectives contribute to a more efficient and responsible operation. It also means prioritizing environmental considerations in every decision, from packaging materials and waste management to every aspect of business park spaces.

While the shift to smart warehousing won’t happen overnight and demands investment and expertise, the benefits for the environment, communities, and businesses are significant.

We stand at a pivotal moment where innovation intersects with responsibility, offering a choice between an inefficient, polluted future or a sustainable, intelligent, and thriving supply chain. The future of smart warehousing isn’t solely about moving goods using technology; it’s about advancing towards a better world.